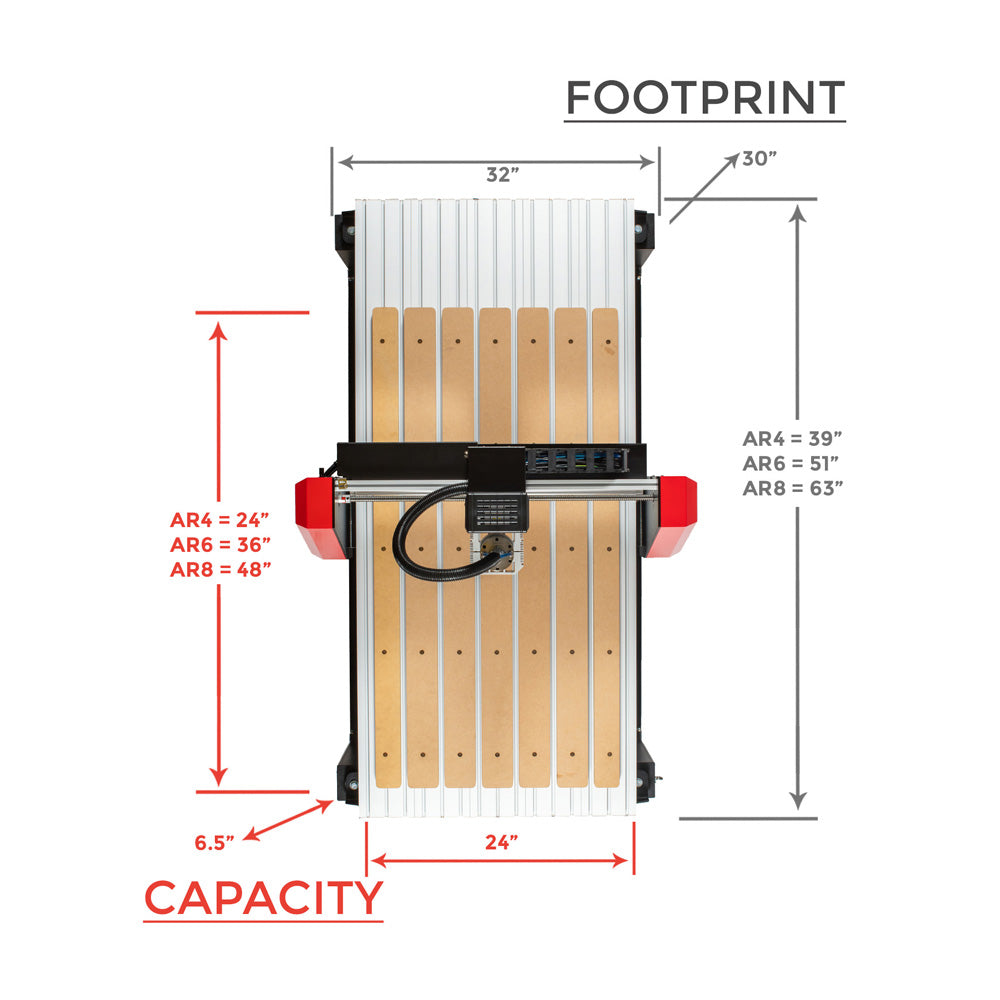

Axiom AR6Pro V6 2'x3' CNC Router

- Price

- $ 8,499

Have questions? Give us a call at 260-637-0054.

These machines ship directly to your shop for $399 (residential & lift-gate delivery services included).

Axiom Precision offers a wide range of machines to address nearly any small-format CNC application. Each machine has been thoughtfully designed and rigorously tested in their Columbus, Ohio facility. These CNCs are engineered from the ground up like a large machine, but they will fit comfortably in your shop. Count on Axiom for accuracy, repeatability and speed without the use of any complex software.

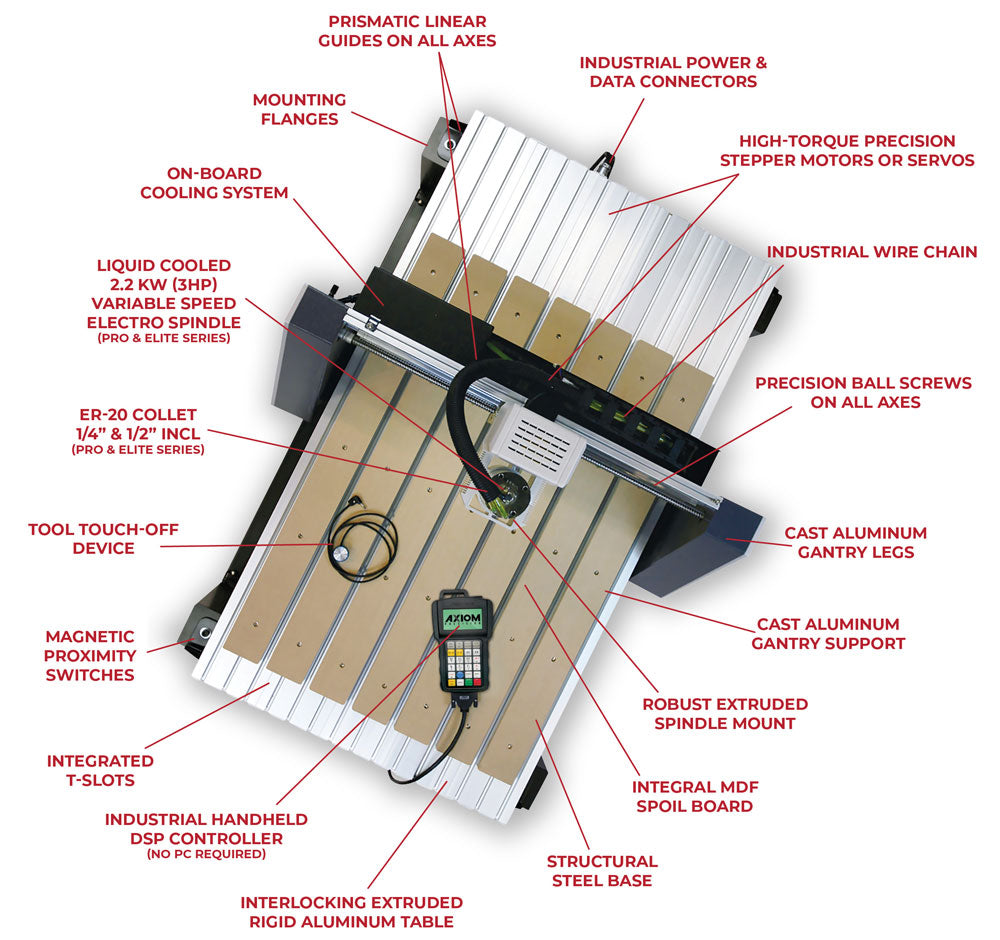

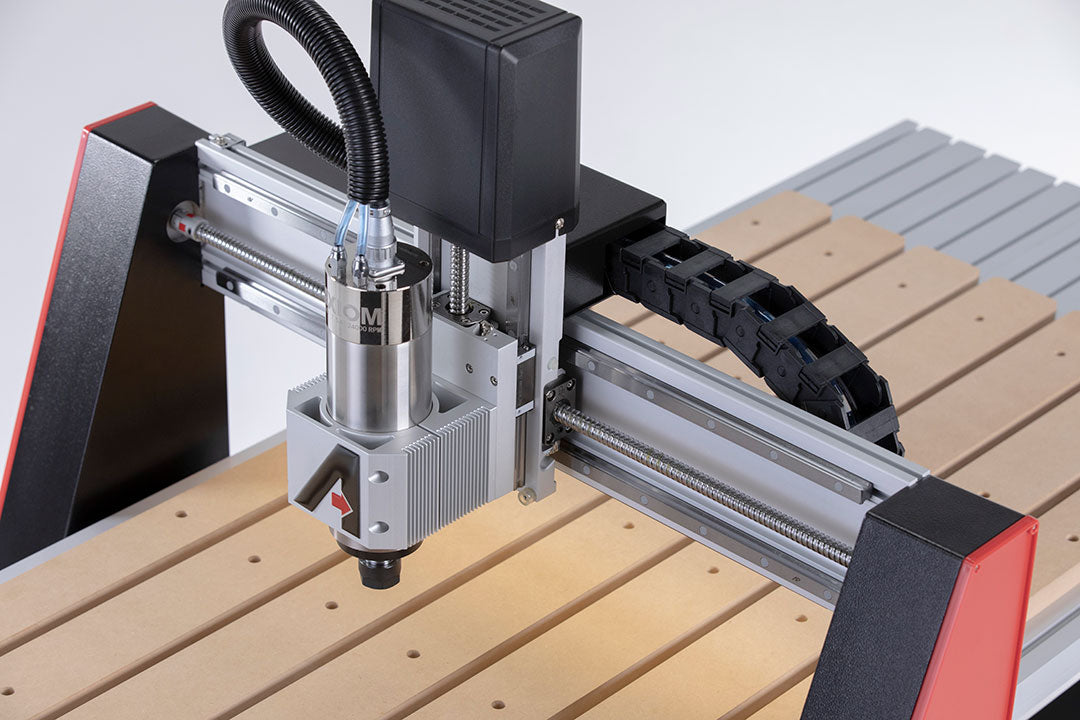

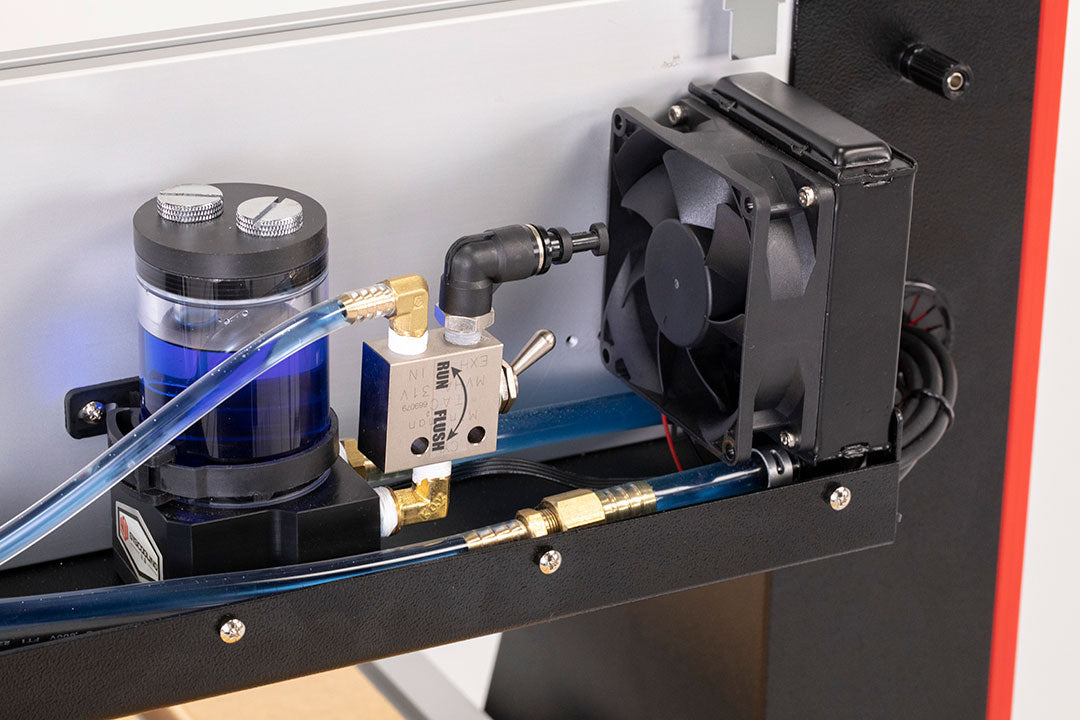

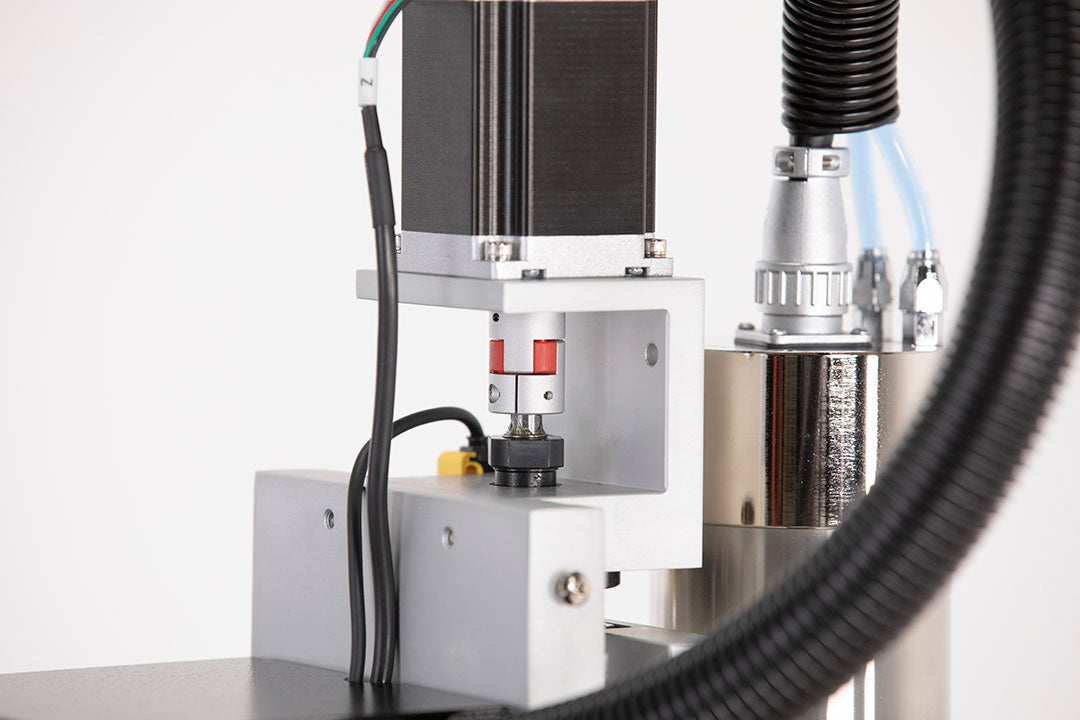

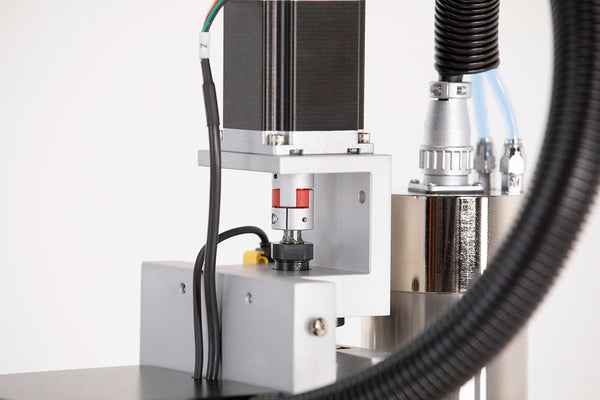

The Pro V6 Series of CNC Routers offers all of the great features you've come to know and love from Axiom, but adds increased holding torque with 48V stepper motors, an improved cooling system, and higher spindle performance thanks to an upgraded VFD. Pro V6 CNC Routers provide a full 6.5'' of gantry clearance and a quiet yet powerful 3hp electro-spindle with integrated liquid cooling system.

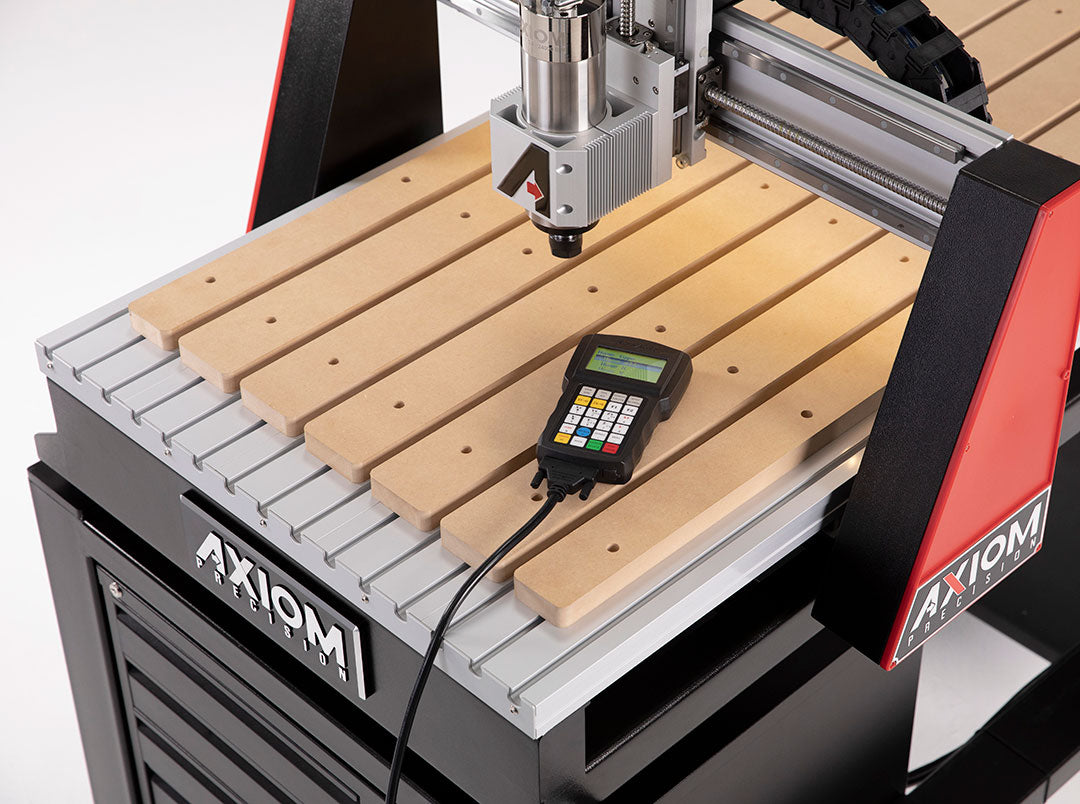

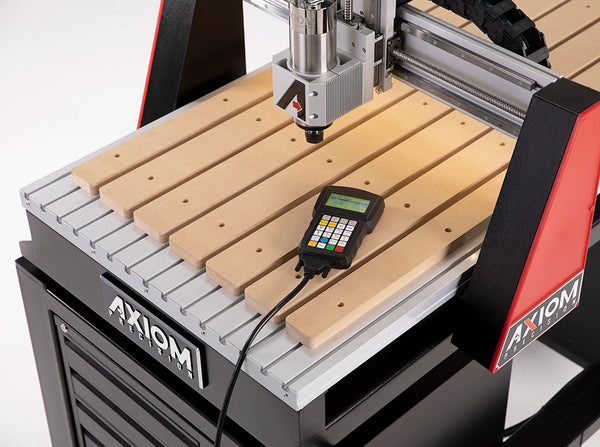

Axiom Pro Series CNC's come with integrated MDF spoil boards to provide the exacting precision you need as they can easily be milled flat for a true perpendicular surface to the spindle. It does not need to be attached to your computer to operate it. Simply transfer your file to the handheld controller via USB storage device. The handheld RichAuto B18 controller is a powerful, lightweight and easy to use controller with over a decade of proven results in demanding applications.

These CNCs come with lifetime technical support. Whether it’s a software or technical question, or just a challenging application, Axiom is there to help — regardless of how long you’ve owned your machine. No invoices, no expiration dates.

Applications:

- Furniture Making: Whether you’re simply cutting out 2D furniture components, producing an accent inlay, or an ornate 3D wood appliqué, the applications for a CNC router within the woodworking trade are nearly countless.

- Fabrication: Need to produce a unique component? Wood, Aluminum, Brass, Composites, Phenolic, Foam, Plastic - If it can be cut with a spinning bit, Axiom Precision can produce it quickly and accurately.

- Sign Making: The ability to use a CNC machining center to carve letters and design elements into wood, plastic and aluminum has transformed the sign industry. Axiom Precision offers the machines, software, and accessories to produce nearly any sign you can imagine.

- 3D Carving: Axiom Precision’s capacity and accuracy make each machine a 3D carving powerhouse. From large three dimensional objects, to fine furniture accents, you’ll quickly produce accurate 3D carvings.

- Prototyping: Axiom Precision offers a small, yet accurate machine to produce one-off components and prototypes.

- Millwork: Reproducing historic architectural components is a snap with Axiom Precision. Brackets, capitals, arches, corbels, moldings and more can all be produced with ease.

Note: Stand and Tool Box sold separately.

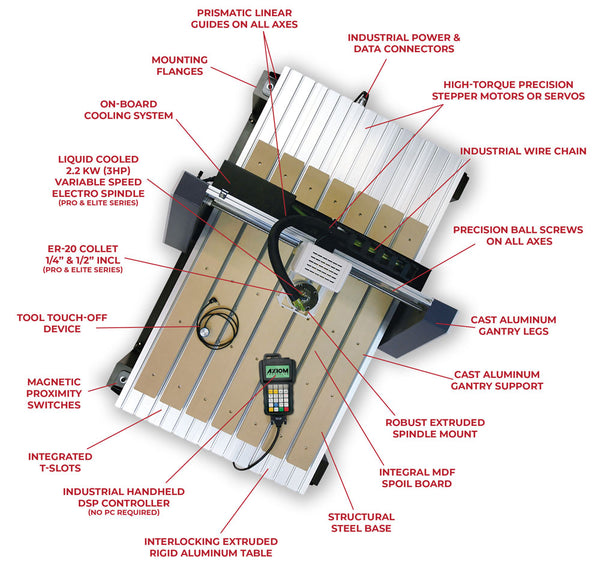

Features

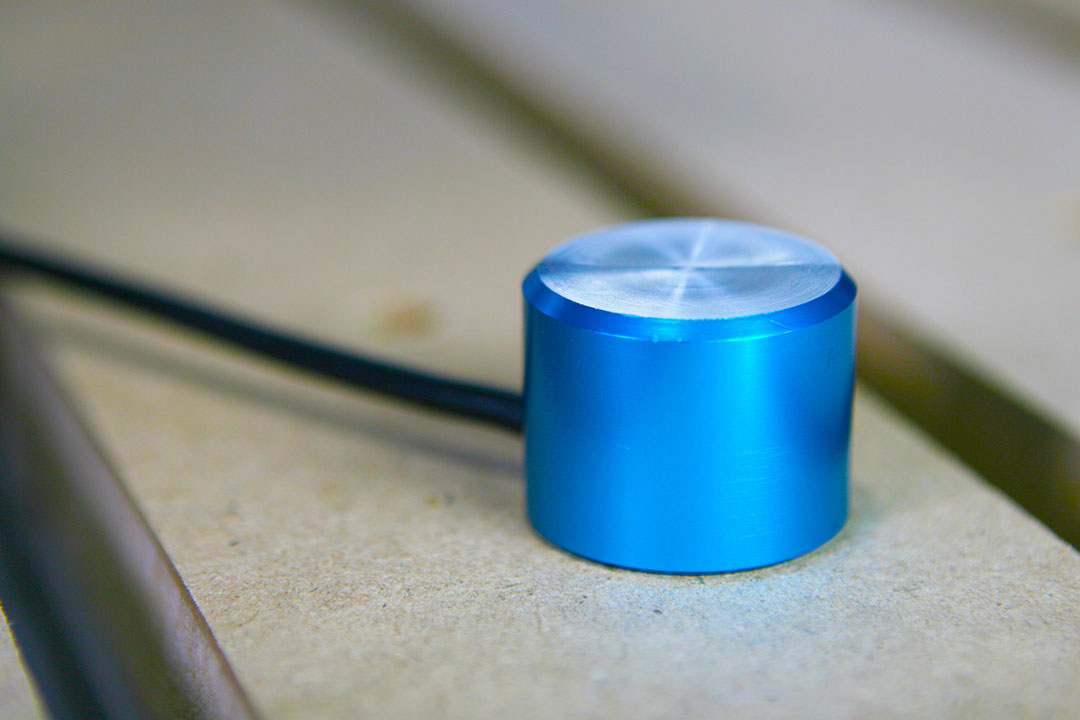

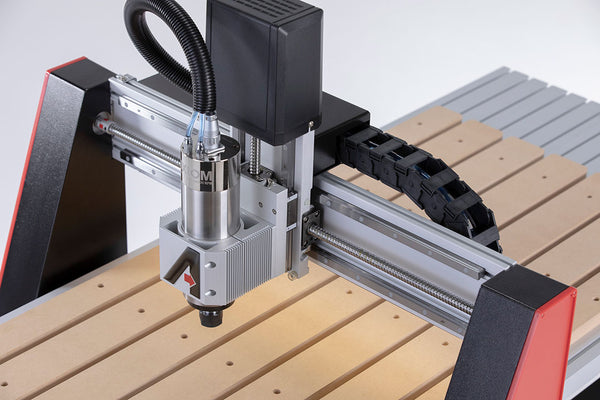

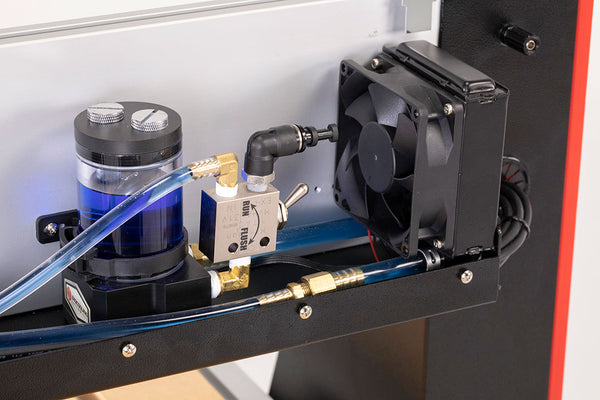

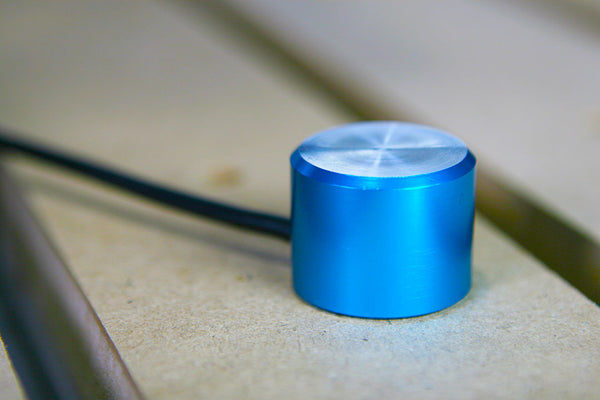

- Powerful & Quiet: Provides a full 6.5" of gantry clearance and a quiet yet powerful 3HP electro-spindle with integrated liquid cooling system and auto tool touch-off plate

- Interlocking Aluminum table: The most rigid, flat and stable surface around

- Structural Steel Frame: Every machine is built on this massive structure

- Cast Gantry Supports: Complex gravity castings virtually eliminate flex

- Proximity Sensors: These magnetic sensors act as your CNC's eyes

- Ball Screws: Found on every Axiom Precision machine

- Onboard Cooling System: No buckets, no hoses, no aquarium pumps. No drama

- Linear Guideways: Minimal friction. Maximum accuracy

- Industrial DSP Controller: No complex software. The hand-held controller is powerful yet easy to use

- Cable Track Chain: Stress-free movement of hoses and cables

- High Torque Steppers & Servos: Fast, repeatable positioning of all axes

- Tool Touchoff Device: Measure your bit length quickly and accurately

- Industrial Data Connectors: No weak links

Stand and toolbox sold separately.

Specifications

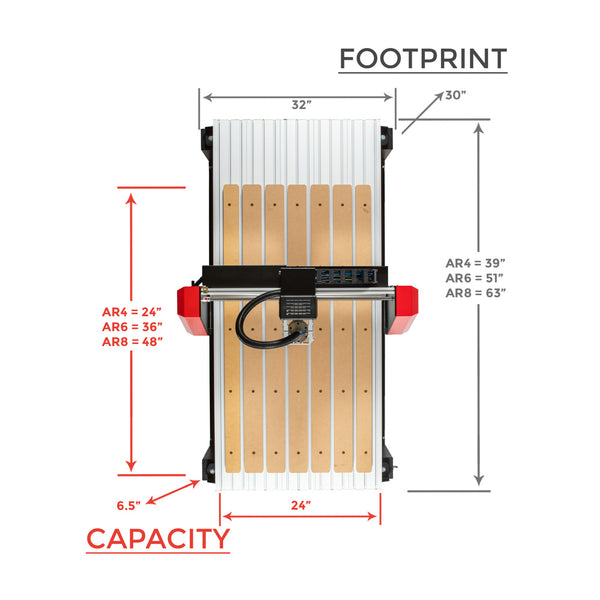

X Axis Travel: 24" (610 mm)

Y Axis Travel: = 35.82" (910 mm)

Z Axis Travel: 5.9" (150 mm)

C axis Travel: 360°

Table Work Area: 28.4" x 51"

Spindle Configuration: ER20

Included Collets: 1/4" & 1/2"

Electro Spindle: 2.2KW

Spindle Speed: 0~24000 RPM

Rapid Shuttle Speed: 300 IPM (5 MPM)

Precision Linear Guideway: X/Y/Z

Precision Ball Screw: X/Y/Z

Ball Screw Diameter: 16 mm

Resolution: +/- .00393" (0.10 mm)

Power requirements: 220 V,50~60 Hz, 10A, 1-Phase

Working Table: High rigidity Aluminum Extrusion

Gantry bridge: High rigidity Aluminum Extrusion

Gantry Supports: Aluminum alloy gravity cast

Gantry Clearance (from table): 6.5" (165.1 mm)

Gantry Clearance (from mdf spoil board): 5.5" (139.7 mm)

Machine Base: All Welded Steel

Frame Machine Dimensions: 51.18"L x 37.36"W x 30.27"H

Shipping Dimensions: 53"L x 39"W x 33"H

Shipping Weight: 360 lbs.

Tool Touch-Off Device: Included

Onboard Cooling System: Included

Controller: Richauto B18 DSP 4-Axis Controller, CNC motion control system, USB port for easy file transfer.