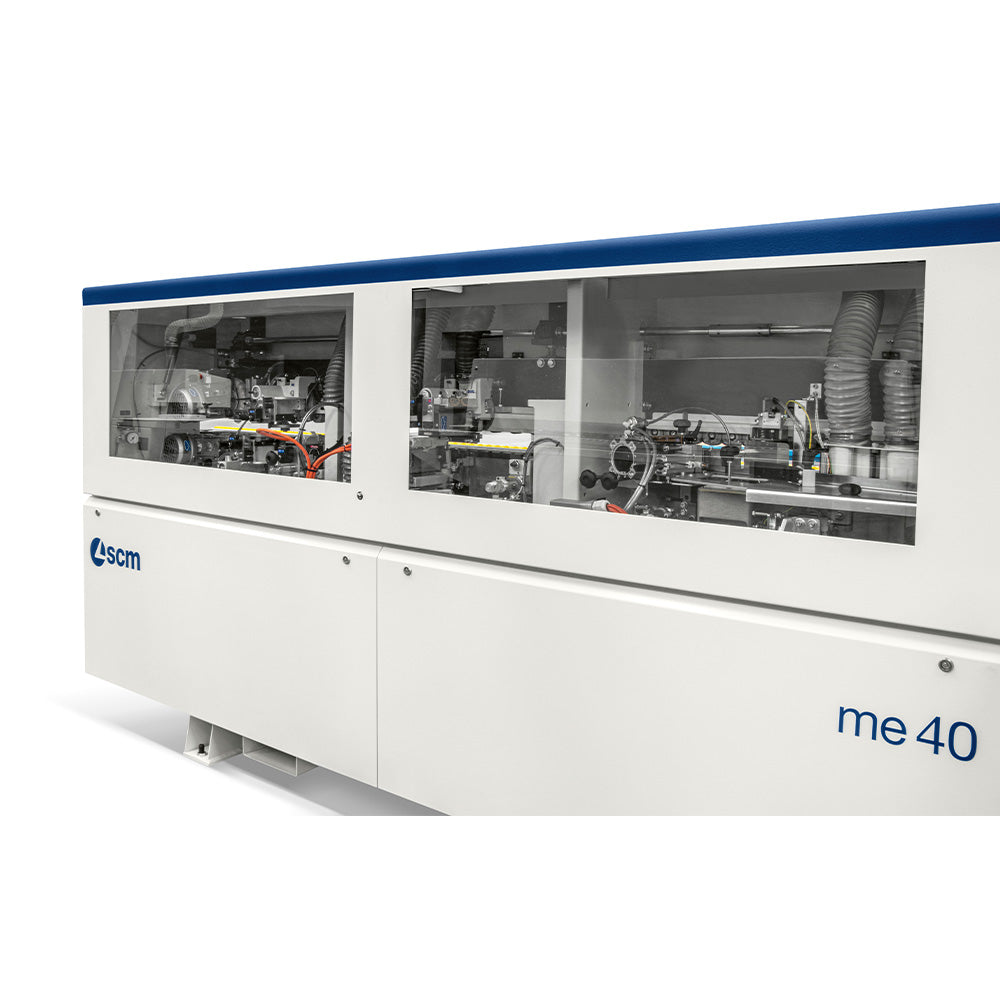

SCM Minimax ME 40ETR Automatic Edge Bander with Pre-Milling & Rounding Unit

- Price

- $ 38,485

Have questions? Give us a call at 260-637-0054.

- Freight included in price*

- Next available July 2025

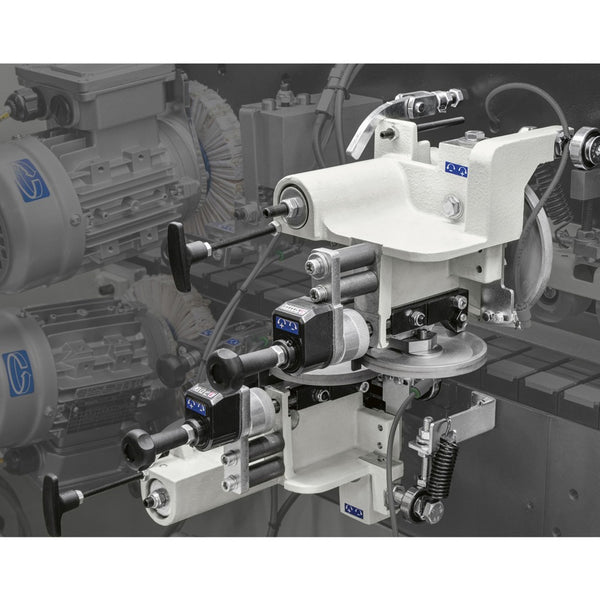

The Minimax ME 40ETR is a 3-phase automatic edge bander with great flexibility for both thin and thick edges. It intends to bridge the gap between a traditional small to midsize edge bander to the more robust equipment used in the Classical line of products. One of the key features is the pre-mill. There is no competition in the U.S. market for such a small, versatile machine, with pre-mill that is so economical!

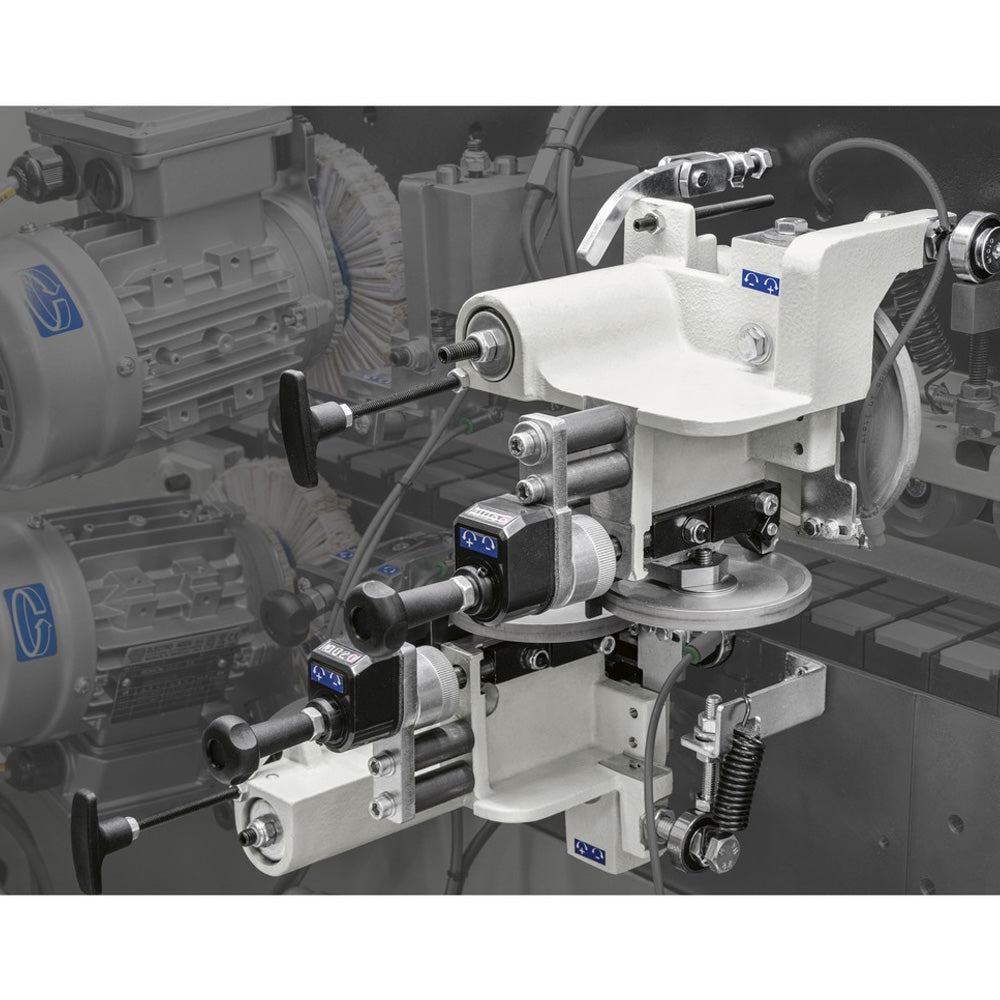

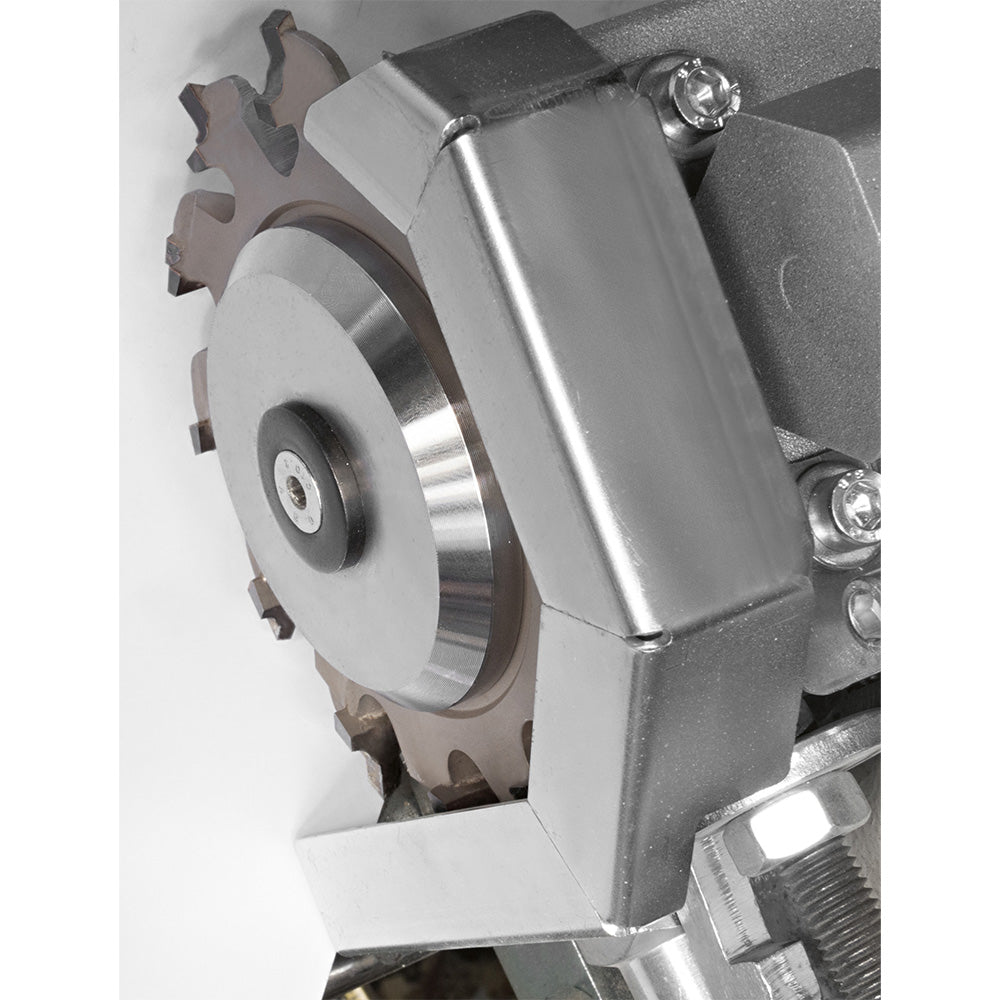

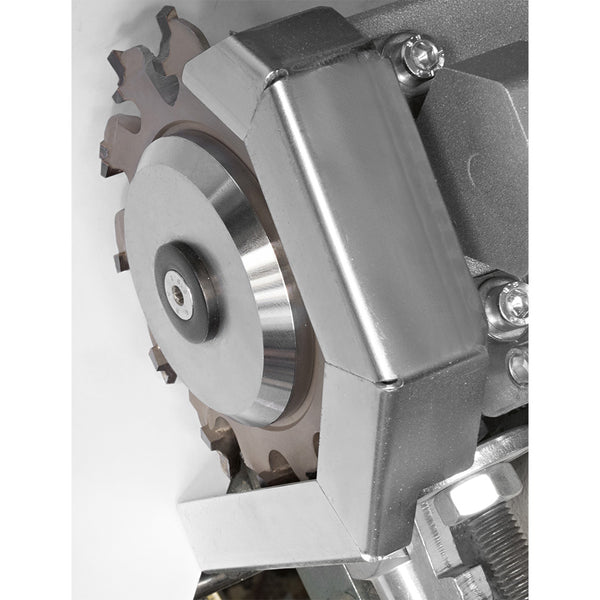

The Minimax ME 40ETR pre-mill unit utilizes two 80 mm diameter diamond tools with opposing rotation and timed intervention that, through the removal operation, corrects any panel imperfections caused by the saw cutting process and panel storage. This allows for a clean edge and a good lineal finish during the pre-mill process. Pre-milling comes with an independent exhaust and air blower for cleaning of the panel during the process. You can carry out vertical adjustments of the tools for use even into the final sharpening phase.

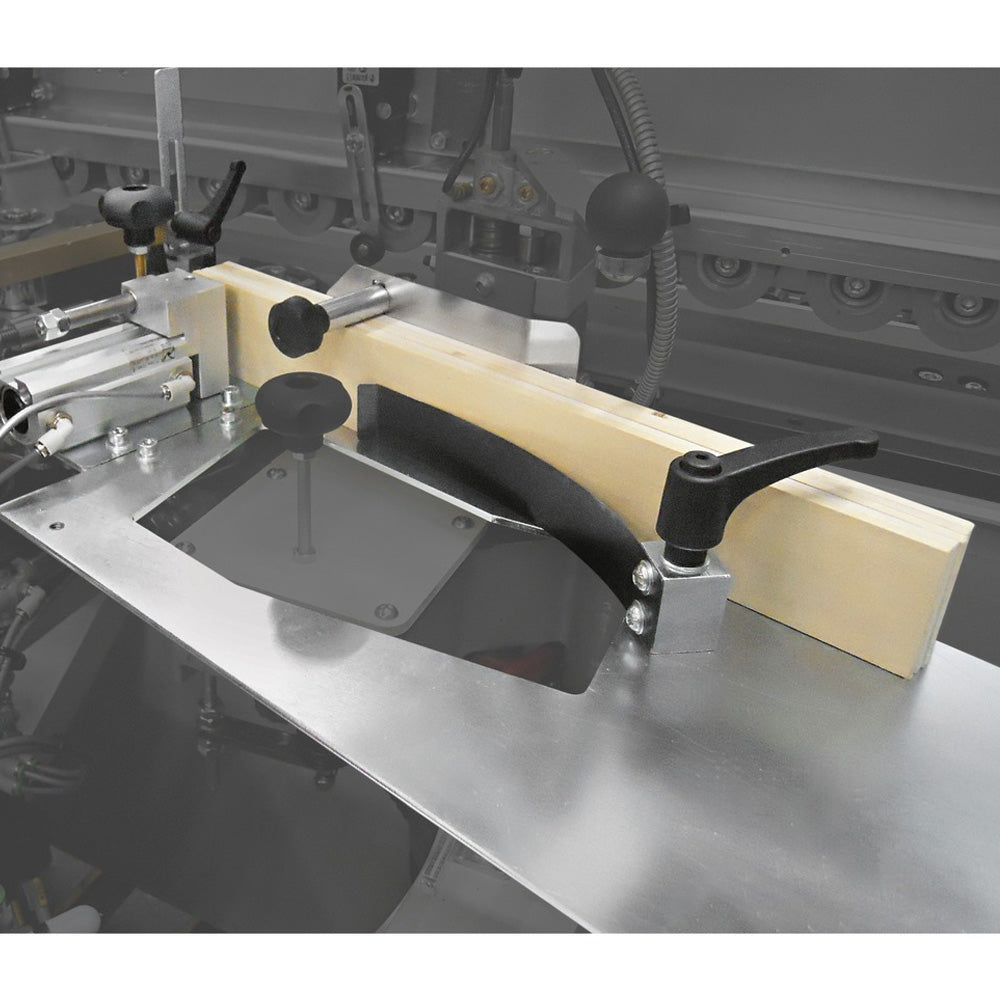

Designed for a perfect finish, the ME 40ETR eliminates transfer marks onto the workpiece. The feed track guarantees high quality processing thanks to the versatility it provides. Users can work with polyurethane glue, perform grooves, and many other applications.

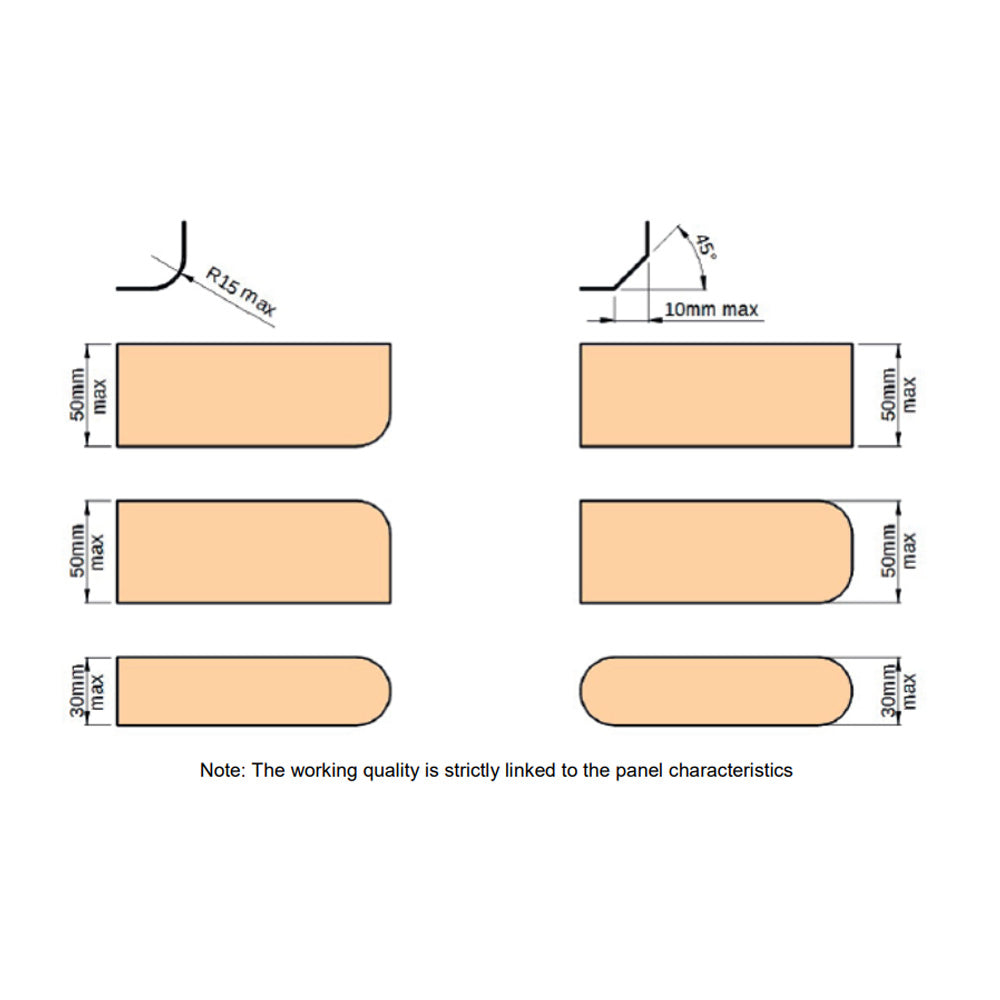

The two stage full corner rounding end-cutting unit cuts and rounds the edge in a single pass at the end of the panel. Driven directly from the control panel it is possible to work with only the end cutting function for thin tape, and 3 mm thick banding or wood. This is the first unit in its class to have this advanced engineering, this small of a footprint, and overall capabilities at a price point that allows the small to medium-sized shop to compete.

The Minimax 40ETR comes with the Eye-S, a touch screen control panel loaded with features to make edge banding applications easy. It allows you to choose the type of material you’re working with (MDF, chipboard, etc.), set the height and thickness of material, and adjust the glue temperature and type, among other things. All edge banding functions are shown graphically on the screen, so it leaves little room for errors or confusion.

Units included on the ME 40ETR:

- Pre-Milling

- Glue Pot

- End Cutting

- Top/Bottom Trimming

- Rounding

- Profile Scraping

- Brushing (Buffing)

A grooving unit is available as an alternative to profile scraping, glue scraping, or buffing unit.

ME Edgebander Comparison Chart >

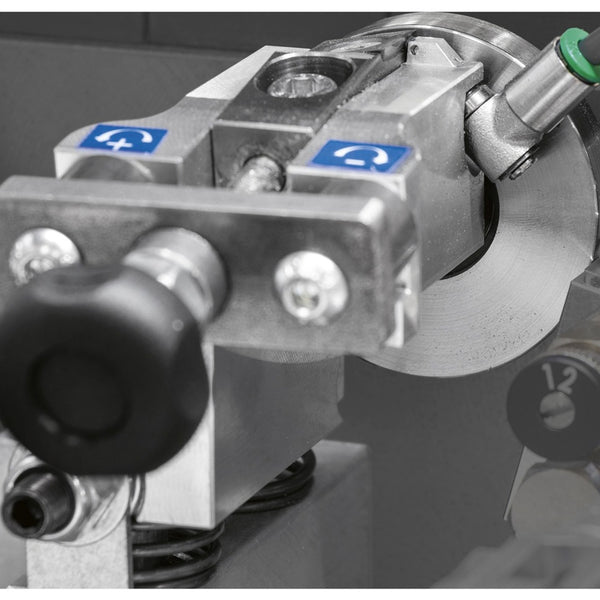

- Intuitive EYE-S Touchscreen Control Panel allows user to set material measurements, control glue temperature, and many other edge banding functions

- Turn the trimming unit as well as the edge scraping unit and glue scraping unit on/off with the push of a button

- Welded steel main frame ensures high rigidity structure

- Top steel presser, complete with two rows of rubber coated wheels mounted on bearings

- Feed track made of high-friction rubber pads slide on two guideways, one round and one flat, to ensure straight movement and resistance to side loads

- Panel support roller can be extended the entire length of the machine

- Interchangeable glue pot is Teflon coated to allow for easy clean up and glue replacement

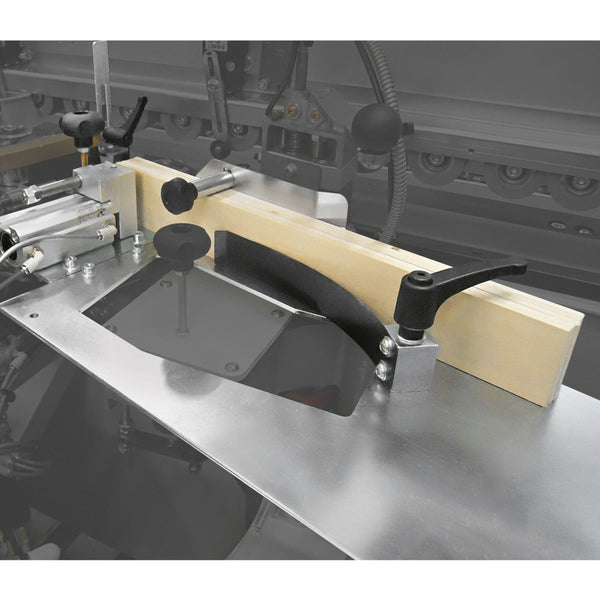

- Automatic loading device for edges in strips

- Anti-adhesive unit prevents glue from sticking to the upper and lower panel surfaces (does not include liquid)

- Pre-milling unit equipped with independent exhaust hoods and an air blower which cleans dust and chips that form on the panel

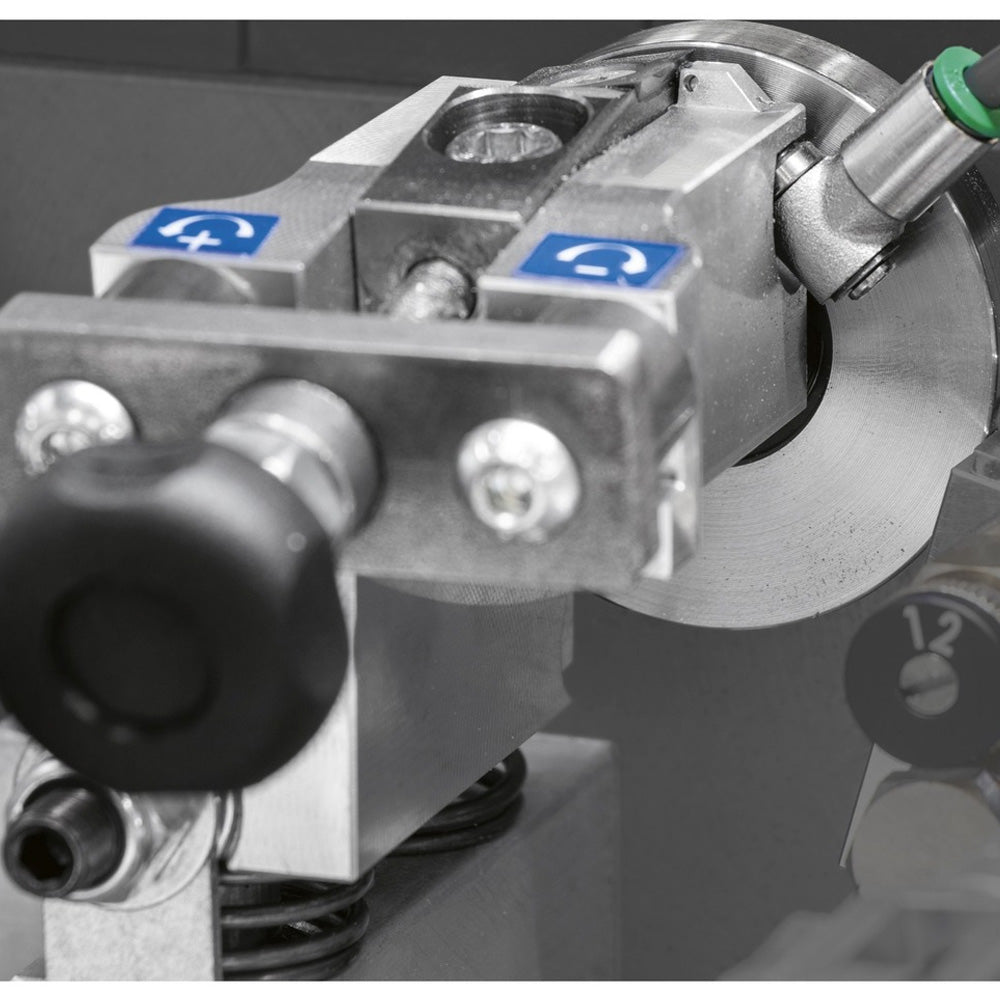

- Top/Bottom trimming unit with multi-radius tool features front rotating copiers with chrome plated surfaces and vertical copying discs for an accurate positioning of tools with reference to the cutting point

- Edge scraping unit with multi-radius tool assures an excellent vibration-free finish

- Brushing unit features tilted, vertically adjustable motors to optimize edge cleaning and polishing

- Internal machine lighting

- Intuitive EYE-S Touchscreen Control Panel allows user to set material measurements, control glue temperature, and many other edge banding functions

- Turn the trimming unit as well as the edge scraping unit and glue scraping unit on/off with the push of a button

- Welded steel main frame ensures high rigidity structure

- Top steel presser, complete with two rows of rubber coated wheels mounted on bearings

- Feed track made of high-friction rubber pads slide on two guideways, one round and one flat, to ensure straight movement and resistance to side loads

- Panel support roller can be extended the entire length of the machine

- Interchangeable glue pot is Teflon coated to allow for easy clean up and glue replacement

- Automatic loading device for edges in strips

- Anti-adhesive unit prevents glue from sticking to the upper and lower panel surfaces (does not include liquid)

- Pre-milling unit equipped with independent exhaust hoods and an air blower which cleans dust and chips that form on the panel

- Top/Bottom trimming unit with multi-radius tool features front rotating copiers with chrome plated surfaces and vertical copying discs for an accurate positioning of tools with reference to the cutting point

- Edge scraping unit with multi-radius tool assures an excellent vibration-free finish

- Brushing unit features tilted, vertically adjustable motors to optimize edge cleaning and polishing

- Internal machine lighting

- Intuitive EYE-S Touchscreen Control Panel allows user to set material measurements, control glue temperature, and many other edge banding functions

- Turn the trimming unit as well as the edge scraping unit and glue scraping unit on/off with the push of a button

- Welded steel main frame ensures high rigidity structure

- Top steel presser, complete with two rows of rubber coated wheels mounted on bearings

- Feed track made of high-friction rubber pads slide on two guideways, one round and one flat, to ensure straight movement and resistance to side loads

- Panel support roller can be extended the entire length of the machine

- Interchangeable glue pot is Teflon coated to allow for easy clean up and glue replacement

- Automatic loading device for edges in strips

- Anti-adhesive unit prevents glue from sticking to the upper and lower panel surfaces (does not include liquid)

- Pre-milling unit equipped with independent exhaust hoods and an air blower which cleans dust and chips that form on the panel

- Top/Bottom trimming unit with multi-radius tool features front rotating copiers with chrome plated surfaces and vertical copying discs for an accurate positioning of tools with reference to the cutting point

- Edge scraping unit with multi-radius tool assures an excellent vibration-free finish

- Brushing unit features tilted, vertically adjustable motors to optimize edge cleaning and polishing

- Internal machine lighting

Specs

Electrical requirements: 3-phase, 220V, 60 Hz, 38 A

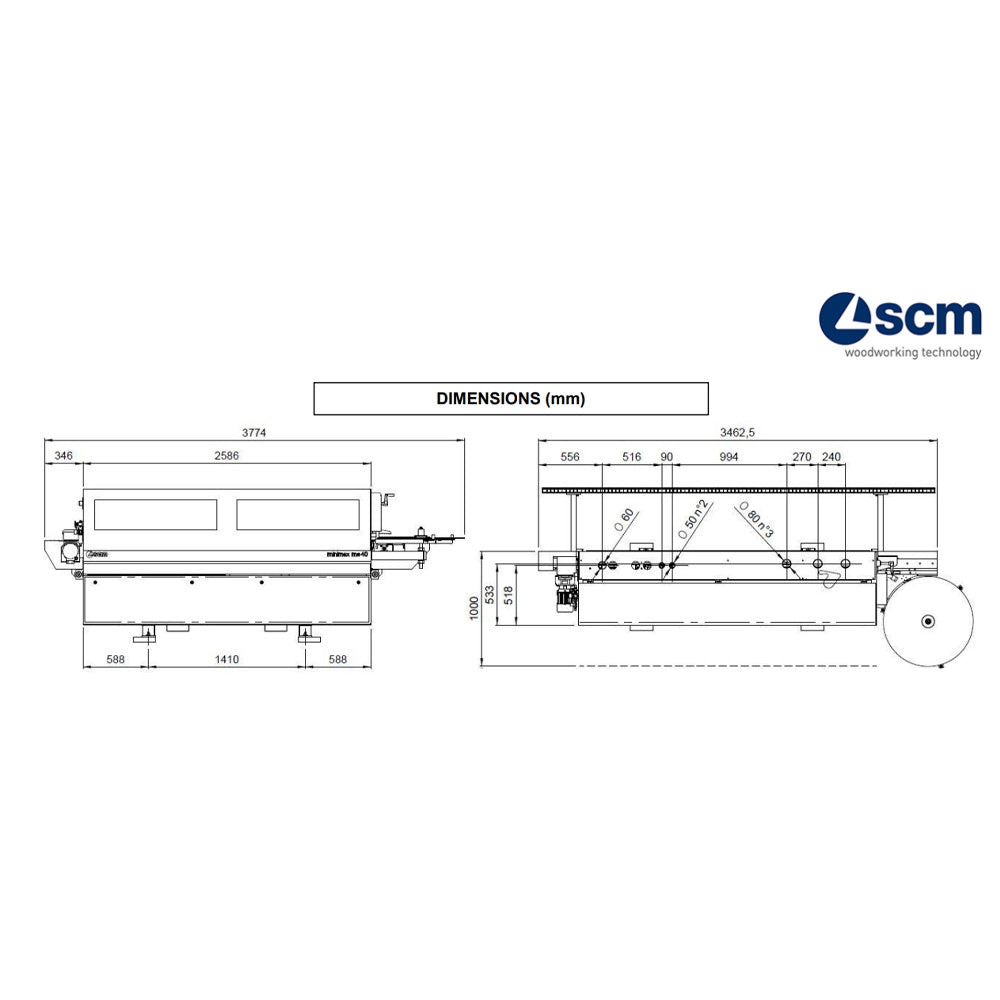

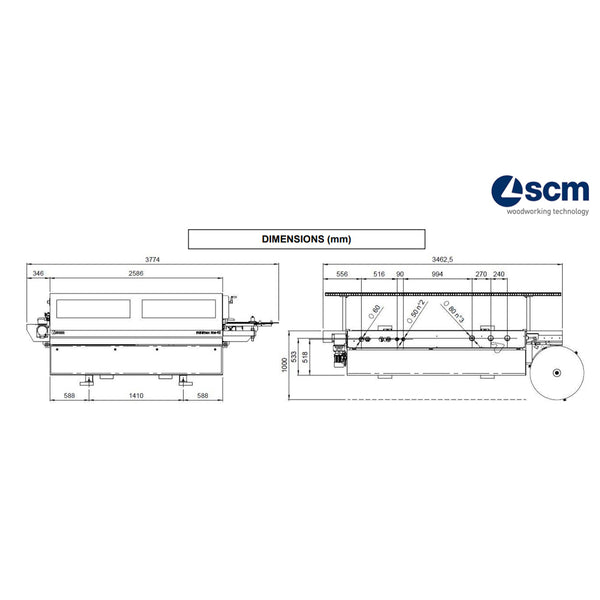

Worktable dimensions: 136.4” x 28” (3,465 mm x 710 mm)

Worktable height: 34.4" (875 mm)

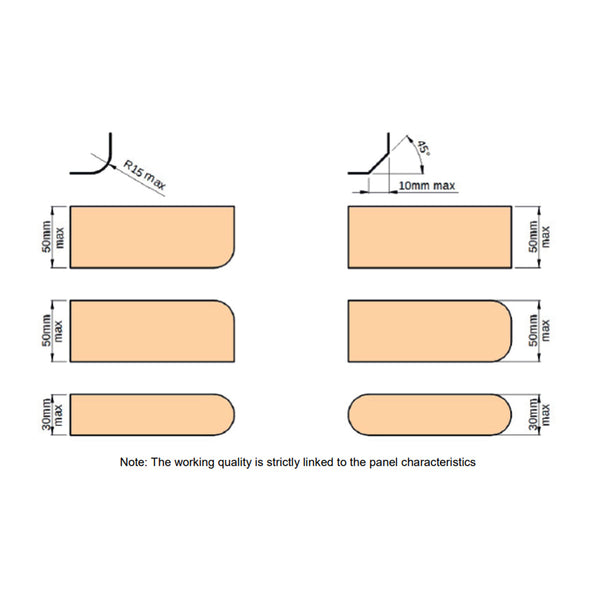

Min / max thickness of rolled edges: .02" - .06" (0.4 - 3 mm)

Max thickness of edges in strips: Up to 5 mm (0.19")

Min. – max. panel height: .315” – 1.96” (8 - 50 mm)

Min panel length/width: 7.48”/4.33” (190 mm/110 mm)

Feed motor power: .73hp (.55 kW)

Feed speed: 30 fpm (9 m/min)

Operating temperature: 68° - 374°F (20° - 190°C)

Specs

Worktable dimensions: 136.4” x 28” (3,465 mm x 710 mm)

Min - max thickness of rolled edges: .02" - .06" (0.4 - 3 mm)

Max thickness of edges in strips: Up to .19" (5 mm)

Min – max panel height: .31” – 1.94” (8 - 50 mm)

Min panel length/width: 7.5”/4.3” (190 mm/110 mm)

Feed motor power: .73hp (.55 kW)

Feed speed: 9 m/min (29.5 fpm)

Operating temperature: 68° - 374°F (20° - 190°C)

Min. required dust collection: 1,082 CFM

Electrical requirements: 220V, 60Hz, 3-phase, 38 A

Pre-Milling Unit

Motor power: 4hp (3 kW)

Diamond cutter: Ø 80mm Z2 H=56

Blade rotation speed: 7,200 RPM

Stock removal: 0 - .08" (0 - 2 mm)

Glue Pot Unit

Motor power: .33hp (.25 kW)

Glue capacity: 2 lbs. (~0.8 kg)

End Cutting Unit

Motor power: .25hp (.19 kW)

End cutting blade: Ø 125 mm Z12

Blade rotation speed: 12,000 RPM

Trimming Unit

Upper/lower motor power: 2x .47hp (.35 kW)

Widia cutters: Ø 55.3 mm Z3

Cutters rotational speed: 12,000 RPM

Vertical/horizontal copying devices: Rotating/rotating

Brushing Unit

Motor power (each): 2x .18hp (.14 kW)

Includes

- (2) Pre-mill diamond cutters

- 2 mm multi-radius tooling set

- Toolbox

Video

*Shipping

Please note: Items being shipped to extremely remote areas or areas with limited delivery access (such as islands only accessible by ferry) may incur additional shipping or freight fees. If your order requires any additional fees other than what is already included in the price, you will be contacted before those fees are applied and before your item ships. This is rare and will not apply to most orders.