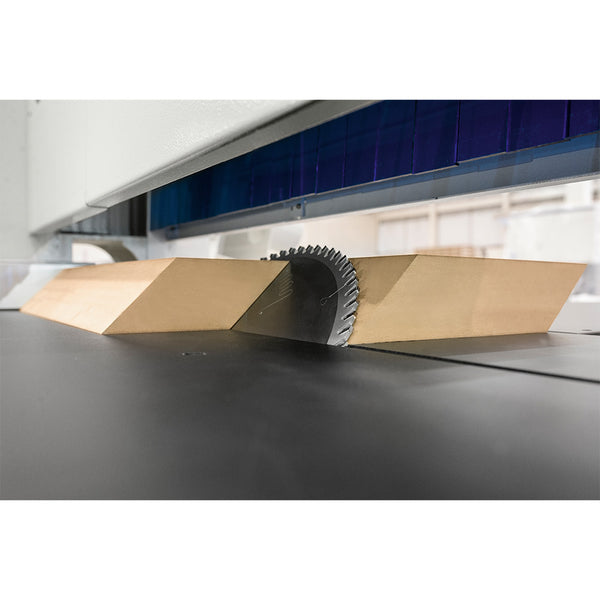

SCM Class PX 350I Circular Saw with Mobile and Tilting Saw Blade Units

Have questions? Give us a call at 260-637-0054.

Note: This machine contains a “starting at” price, meaning that the price shown is the base cost for the standard features. However, this machine is made to order, and you can choose which options and accessories will best suit your needs. The following description is applicable to the standard machine. If you are interested in configurations, please see the “Optional Add-Ons” tab for available options for this machine. Contact us at 260-637-0054 or sales@oaktreesupplies.com with any questions or to place your order.

The Class PX 350I from SCM is unlike anything you've ever seen. It's not a beam saw or a sliding table saw, but a circular saw with a mobile carriage and tilting blade. This saw works in conjunction with the SCM Thundercut App to allow you to make more repeatable cuts without sacrificing accuracy and precision, as well as wasting less material.

The PX 350I lets you achieve a perfect cut of veneered or solid wood panels both at 90° and tilted up to 46°. The "READY" electronic control panel allows motorized control of both the tilting blade unit and the rear stop for immediate positioning. It also has a memory capacity of up to 99 programs, and features a calculator and hour counter.

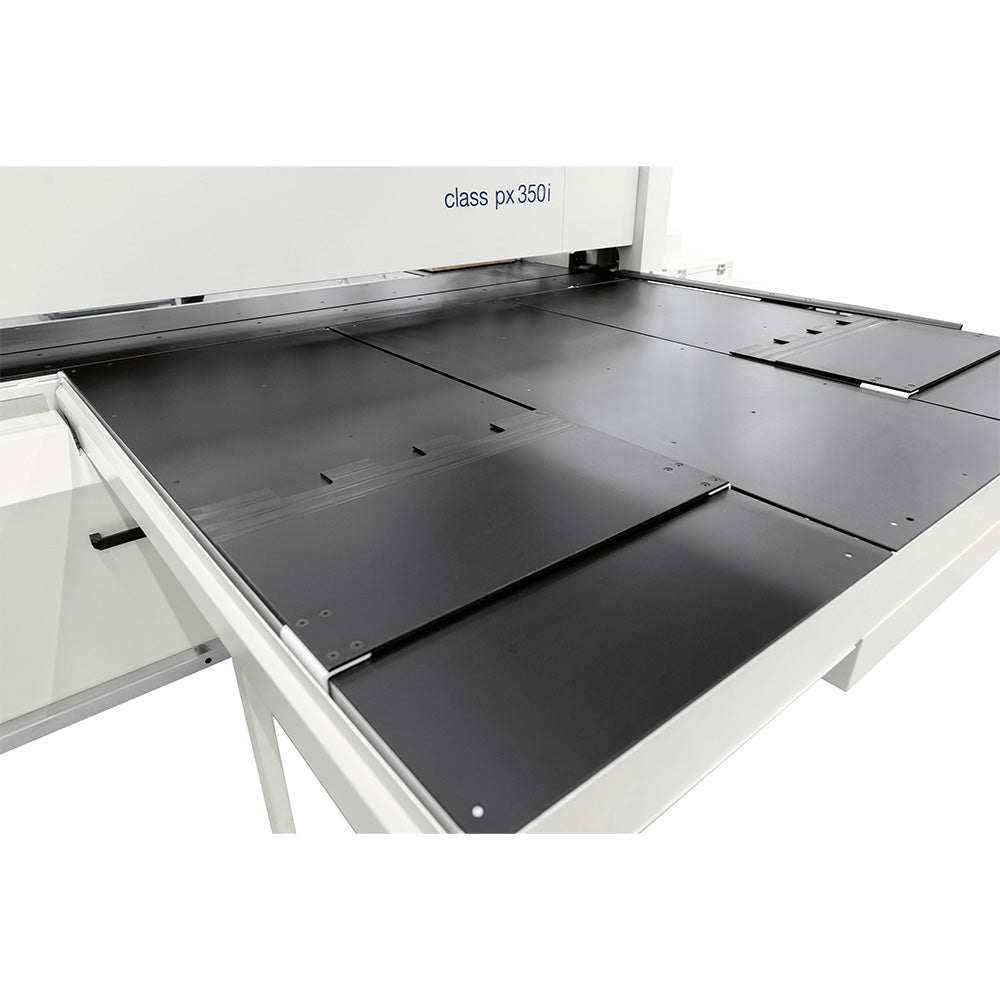

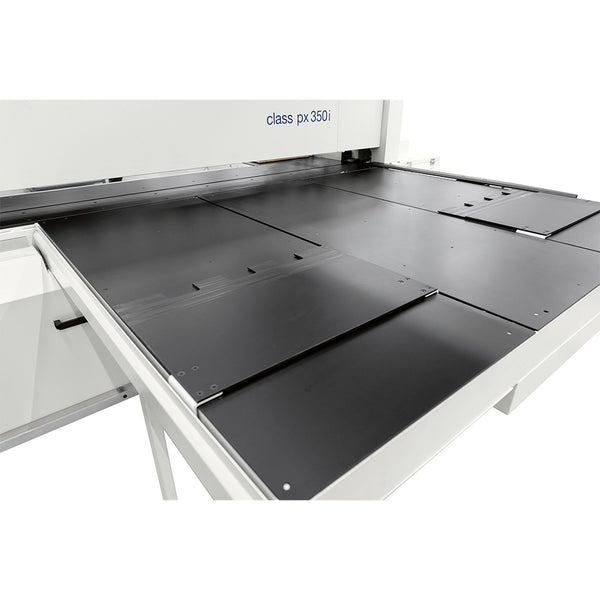

The sturdy telescopic squaring fence features a metric scale that is tilted towards the operator for easy reading, and 2 reversible stops. The large fixed table guarantees a stable support for panels up to 2,500 x 3,000 mm (98.4" x 111").

Thundercut App:

- Manage your machine stock and the material and panel magazine

- Create and modify projects, import projects from the main furniture design software ("cpout" file format), import cutting lists

- Optimize cutting lists, choosing from one or more proposals of the optimization software integrated into the App

- Set the machine for each cut thanks to the simple and intuitive graphics of the 3D sequencer that guides the operator at each step

- Print labels with bar codes to identify the various panels for further processing

Features

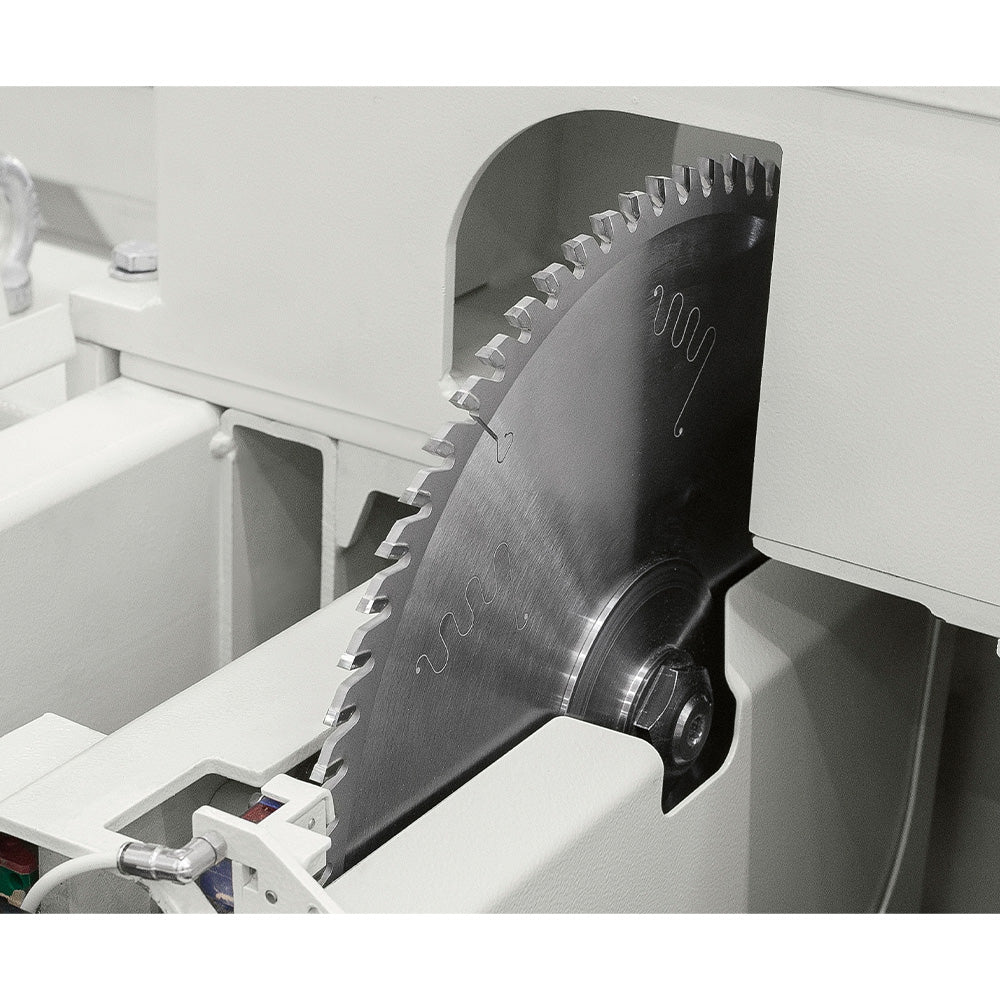

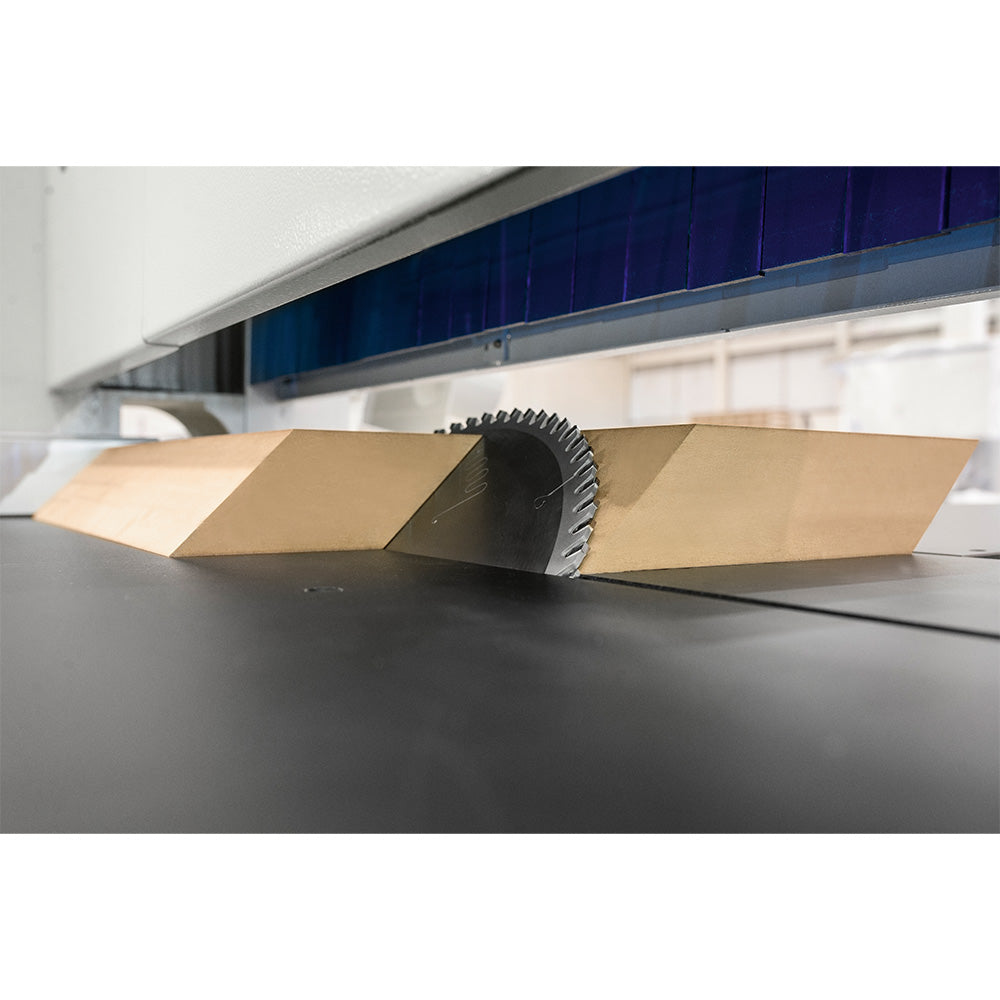

- Engraving and cutting function with the same blade for perfect alignment of the two cuts

- Panel length detecting system for cutting cycle optimization

- Adjusting system for the engraving depth with numerical readout to easily find the ideal setup

- Blade is completely covered during cutting cycle thanks to the pressure beam featuring safety plastic strips

- Simple and intuitive “READY” electronic control for immediate use of the machine

- Telescopic squaring fence with extension up to 2,500 mm and installed on large fixed table for the panel support complete with 2 stops, a metric ruler tilted towards the operator, and a roller for workpiece support up to 1,900 mm

- Motorized and programmed rear fence with positioning from 9 to 1,300 mm

- Rear table with double motorized stop

- 1 fixed front table + 1 mobile front table

- Emergency and working cycle start pushbuttons positioned on the mobile control (extremely useful when machining very large dimensioned workpieces that prevent an easy and safe access to the main control panel)

Specs

Max. squaring stroke: 8.5" (2,600 mm) [10.5" and 12.5" options]

Blade tilting: 0 ÷ 46°

Max. saw blade dia. (cutting): 13.75" (350 mm)

Max. saw blade dia. (engraving/cutting): 11.75" (300 mm)

Max. saw blade projection (D350) from table at 90°/45°: 4.12"/2.81" (105/72 mm)

Max. saw blade projection (D300) from table at 90°/45°: 3.12"/1.94" (80/50 mm)

Blade rotation speed: 4,000 RPM

Cutting width on rear fence: 51.1" (1,300 mm)

Motor power: 9hp (7 kW)

Nominal extraction air consumption: 1,550 m3/h (900 CFM)

Exhaust air speed: 20 m/s (66 ft/s)

Exhaust hoods dia. (2 outlets): 120 - 100 mm (4.69" - 3.87")

Overall dimensions: 12.7' x 10.5' x 4.5' (3,859 x 3,196 x 1,368 mm)

Optional Add-Ons

- Additional mobile table: 15.8" x 53" (400 x 1350 mm) table for supporting large panels. (88.81.33)

- Angular cutting device: Features telescopic fence with flip-over stop for cuts up to 1,500 mm, table for angle selection, and digital readout for stop position. (88.81.36)

- Angular cutting device with digital readouts for stop position and angle tilting (88.81.38)

- Class PX 350I with 2,600 mm (8.5') squaring capacity (R0.08.09)

- Class PX 350I with 3,800 mm (12.5') squaring capacity (R0.08.13)

- Telescopic squaring fence with 3,200 mm extension: Installed on large fixed table for the panel support, complete with 3 stops and a roller for workpiece support up to 1,900 mm. (57.03.61)

- Telescopic squaring fence with 2,500 mm extensions and digital readout flip stops: Installed on large fixed table for panel support, complete with 3 stops equipped with digital readouts and detecting system on magnetic band, plus a roller for workpiece support up to 1,900 mm. (57.03.62)

- NC blade projection on the READY control panel (57.03.70)

- Saw carriage speed reduction: Min/Max 5.5 - 14 m/min. Recommended for cutting plastic materials. (57.03.57)

- Speed inverter: Electronic speed change from 2,100 to 5,200 RPM. Recommended for cutting plastic materials. (57.03.71)

- Cutting line laser (57.03.72)

- Adjustable tablet holder: Positioned on mobile control panel. Compatible with 7" to 13" tablets. Includes USB port on control panel for power supply. (57.03.56)