SCM Class TF 130E Fixed Spindle Shaper

Have questions? Give us a call at 260-637-0054.

Note: This machine contains a “starting at” price, meaning that the price shown is the base cost for the standard features. However, this machine is made to order, and you can choose which options and accessories will best suit your needs. The following description is applicable to the standard machine. If you are interested in configurations, please see the “Optional Add-Ons” tab for available options for this machine. Contact us at 260-637-0054 or sales@oaktreesupplies.com with any questions or to place your order.

A must for the serious woodworker, the Class TF 130E is the SCM shaper that combines quality and value for your investment. It has a very robust structure and all the controls can be accessed on the front of the machine for easy use. The TF 130E features powered lifting with digital readouts.

Monoblock technology is used in the design and fabrication of this base. The solid, welded base undergoes a treatment called normalization which stabilizes the metal and assures exact tolerances. All machine mechanisms are mounted, aligned, and referenced to the base. This design is vastly superior to frames that are bolted together and have no true reference point.

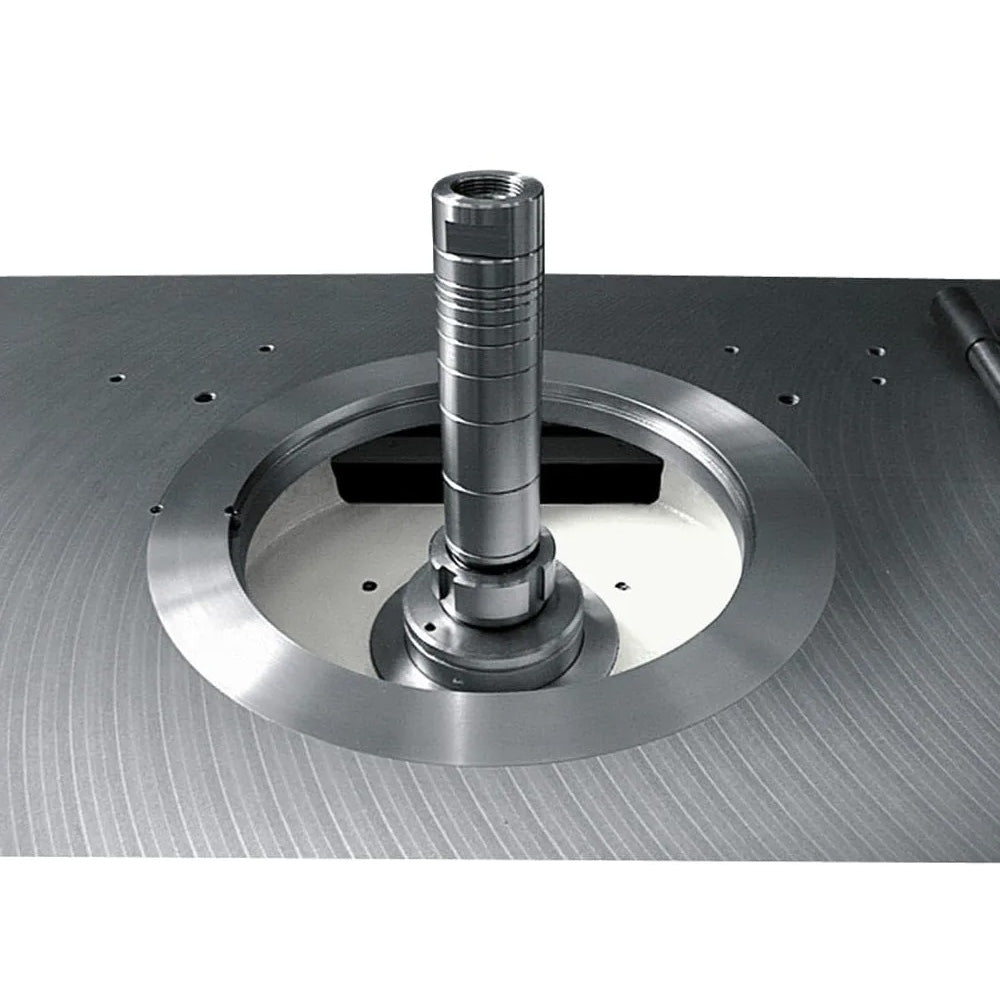

One thing that can degrade the quality of finish from a shaper is the vibration transmitted from the spindle to the cutter. Minimizing vibration is even more critical when cutting tall profiles or using stacked tooling. SCM ensures maximum quality in its shapers by using very large spindle assemblies whereby the increased mass of the spindle absorbs vibrations and eliminates whipping action at the top of the spindle.

A standard feature on the Class TF 130E is the MK 5 interchangeable tapered spindle. This feature allows the use of different spindles for various tooling with different spindle diameters. An upgrade to a larger shaper does not mean that all tooling needs to be replaced. Special tools can continue to be used simply by changing out to a different spindle. A 1-1/4” spindle comes standard.

The Class TF 130 comes standard with a large shaper hood with memory pins. If removed, the hood will go right back into the same position, so it is accurate and repeatable. The fences are adjusted by means of a mechanical hand crank that features a digital (mechanical) readout of the fence positioning. This convenient feature makes it simple to set up the hood for a number of different profiles and operations.

Features

- Powered tool-holder shaft lifting, complete with electronic digital readout of working height

- Spindle moulder fence with mechanical adjustment

- Spindle moulder fence with continuous linear adjustment by handwheels accessible from machine front:

- *adjustment of entire fence in respect of tool diam.

- *adjustment of entry fence for thick removal

- Mechanical readout for the adjustment

- Wooden tables and connecting bars

- 250 mm max. tool diameter

- "FAST" section table replacing the table rings to optimize the working support under the cutting tool, with

- manual external adjustment

- 3,000 / 4,500 / 6,000 / 7,000 / 10000 RPM spindle speeds

- Electric speed display dial (CE and electrical protections versions)

- Electrical presetting for feeder (CE version)

- Reverse spindle rotation with electrical interlocking for reverse operation

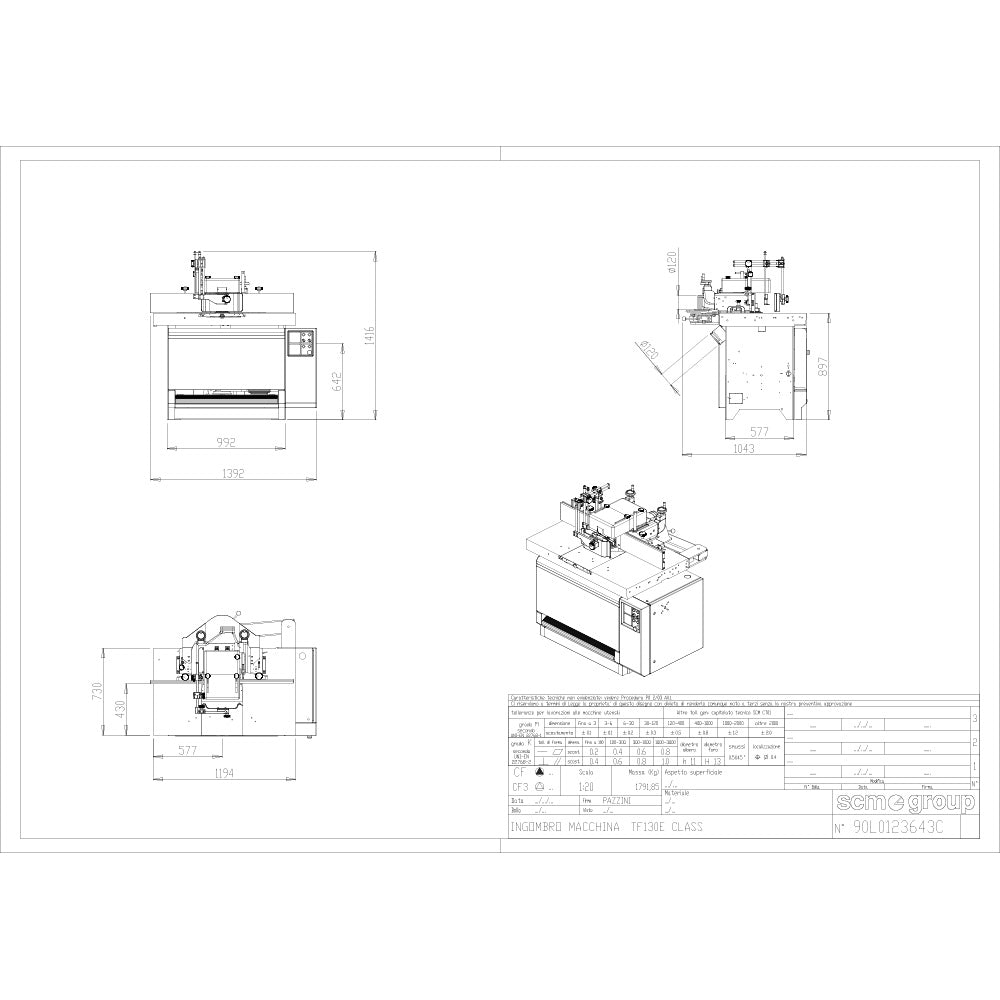

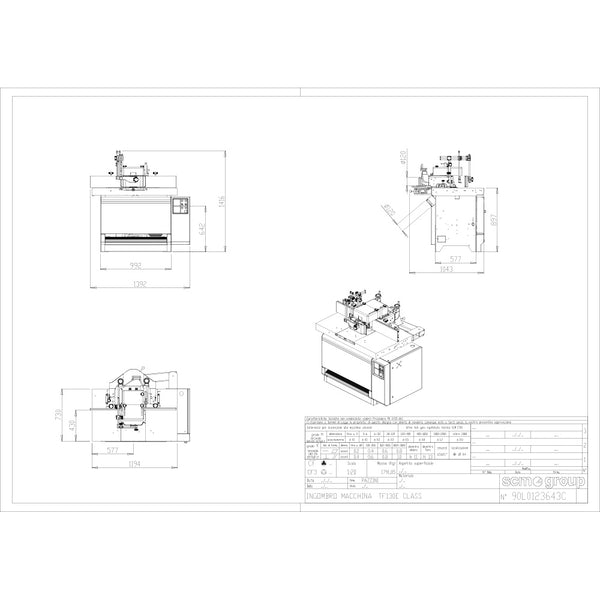

Specs

Work Table dimensions: 1,200 mm x 730 mm

Working length of spindle (C.E.) dia. 30-35 (40-50): 140 (180) mm

Spindle base projection from table: 52 mm

Spindle base projection from table with interchangeable spindle: 92 mm

Max tool dia. retractable under work table with rings (with "Fast" section table): 300 mm x 85 mm

Spindle fence stroke w/ mechanical programming (positioning with respect to the spindle axis): 125 (from -125 to +125) mm

External dia.of exhaust outlet on spindle moulder hood: 120 mm

External dia. of exhaust outlet on base (for the forced electrospindle aircooling 7.5 kW): 120 mm

Air flow speed of exhaust system: 20 M/sec

Exhaust system air consumption: 1,700 M3 sq./hr

Optional Add-Ons

- "LL" version for profiling: Features 2 cast-iron worktable side extensions with 2,500 mm total length for long workpieces, a front support bar to facilitate larger workpieces, and an emergency push button. (88.80.46)

- Carriage on fix table: ±60° swiveling fence with mobile stops, telescopic extension, and eccentric clamp. For small tenoning operations. (88.80.14)

- Manual feeder support: Vertical adjustment with reference to the workpiece thickness, and mechanical digital readout of the position. Horizontal adjustment with reference to the tool diameter. (88.80.40) Note: Requires "upper mobile control panel" option (57.02.60).

- Additional MK5 spindle (88.80.17)

- MK5 right tool taper: Complete with ER 32 type clamp. 1/2" diameter. (88.80.25)

- MK5 left tool taper: Complete with ER 32 type clamp. 1/2" diameter. (88.80.26)

- FLEX system: Instantly retracts and re-positions the fence. (57.02.22)

- Upper mobile control panel (57.02.60)

- Electrospindle: 14hp (11kW). (57.00.64)

-

"TL" version for tenoning profiling: With manual feed tenoning carriage that includes eccentric clamp, telescopic tilting fence with 4 reference stops, anti-splinter device, infeed table extension with adjustable front supporting bar, tenoning hood with exhaust outlet, and emergency push button. Max. tool diameter is 300 mm. (57.00.01)

-

PRO-10 "TL" version: With manual feed tenoning carriage sliding on THK guides through recirculating ball bearing pads. It can easily be excluded from work table. (57.01.05) This version features:

- ± 45°tiltable telescopic fence with reference to the feed

direction - Telescopic tilting fence with 4 reference stops for programming workpiece length

- Worktable with side extensions (2,500 mm total length) complete with adjustable front support bar for large workpieces

- Eccentric clamp

- Anti-splinter device on fence with reference stop

- Tenoning hood with exhaust hood

- Emergency pushbutton

- Operator arm protection

- ± 45°tiltable telescopic fence with reference to the feed